Your Onshore British Manufacturing Partner

Contracts Engineering Ltd (CEL) is a national contract manufacturer that focuses exclusively on manufacturing for clients who are OEM’s and TIER I’s with a UK factory footprint. We are one of the largest contract manufacturers in the Southeast with plans to be one of the largest in the UK by 2028.

We provide a range of in-house manufacturing, supply chain and quality assurance services to our clients. We focus on being their onshore supply chain partner. Currently we process and mechanically assemble components and sub assemblies manufactured from ferrous and non-ferrous metals.

This means that we focus on meeting our clients’ needs so that they can count on their supply chain partners, reduce complexity and focus on their growth plans, as well as their customers’ requirements.

YOUR FULL SERVICE MANUFACTURING PARTNER

Contracts Engineering Ltd is an ISO 9001:2015 fully integrated precision manufacturer based in Sittingbourne, Kent, UK. Our +30,000 sq ft factory operates across two shifts per day, giving us maximum flexibility in production, and allows us to complete high-volume requirements with short lead times.

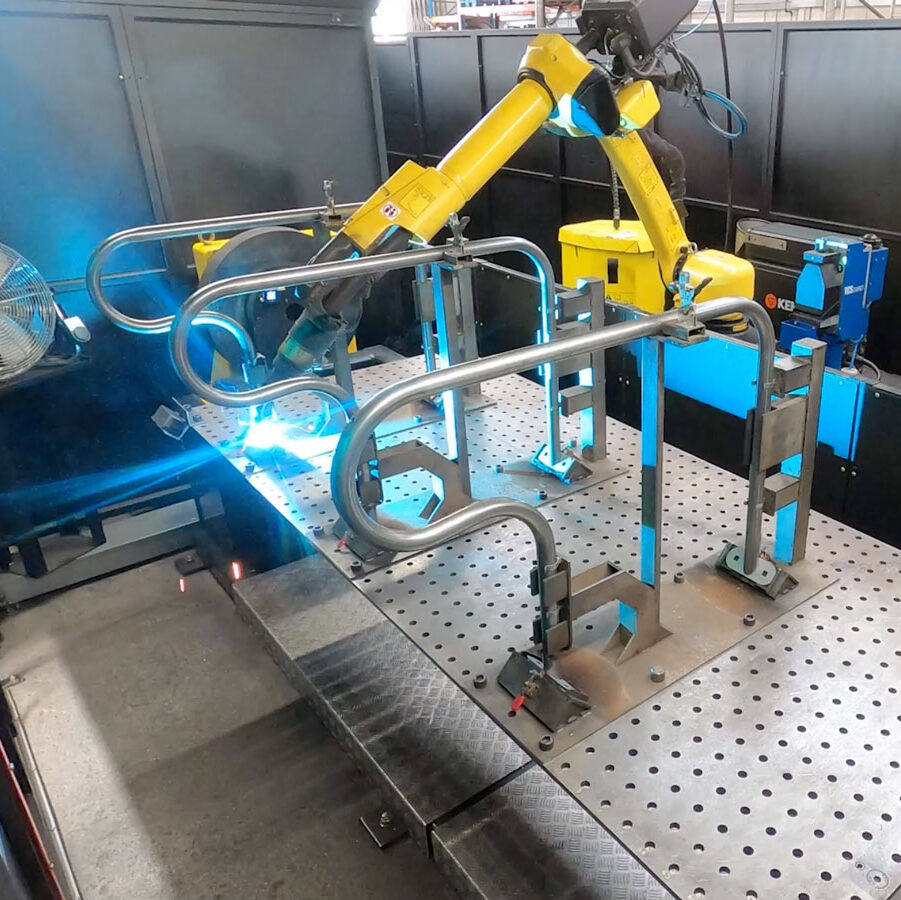

We perform all metal fabrication in-house using our modern CNC machines and welding capabilities. We work with our supply chain on metal finishing processes such as powder coating, galvanizing, anodizing and plating, and regularly work with mild steel (including pre-galvanized and Zintec), COR-TEN steel, stainless steel and aluminium, and occasionally with brass and copper.

Quality services shipped worldwide

Our customers are located throughout the UK and products are regularly shipped throughout Europe, the Middle East and North America. Our main end markets include commercial industries such as light infrastructure, street furniture, construction, design installations and hard landscaping equipment. Our industrial end markets include extraction & ventilation, food processing and niche engineering equipment companies.

FOCUS ON QUALITY AND ON TIME IN FULL DELIVERY

Using ISO 9001 and internal Quality and Delivery metrics, we consistently impress our customers. At Contracts Engineering, all staff monitor two Key Performance Indicators (KPIs), Quality Spills and On-Time-In-Full delivery. The Directors and Managers review these every week and all staff discuss monthly results during an All-Hands meeting. Our modern, SQL-based ERP system, coupled with our ISO 9001:2015 accreditation with the British Standards Institute and internal policies support our continued drive toward improved quality and production efficiencies.

Frequently Asked Questions

Yes, we exclusively manufacture metal components for OEMs and TIER 1 companies, providing seamless integration into your supply chains and adhering to your stringent quality standards.

Our team and operations are built around providing production runs, and we do not pursue project-based work, such as point-of-sale, retail fittings and fit-outs, all of which disrupt the steady flow of production work

We are a national contract manufacturer and one of our USPs is that we only manufacture production runs for OEM and TIER 1 companies. Having this focus aligns the whole team around meeting your requirements.

During an exploratory sales call we can discuss what your specific challenges are and how Contracts Engineering will address them. For example, it could be that:

- Your requirements are growing more quickly than your supplier(s) can keep up with

- You have existing or new Supply Chain Integration and/or Quality Assurance requirements that your current supplier(s) cannot meet

- You are looking to move manufacturing to the UK, reshoring or otherwise

We specialise in manufacturing high-quality, production-ready metal components for OEMs and TIER 1 companies. While we do not manufacture custom or bespoke parts, we do produce prototypes for production runs to ensure a smooth transition from initial manufacture to mass production.

We refer you to our case studies.

We like to start with a discussion around your requirements and our services, which is conducted by our sales team. Once we have engineering drawings for review, we conduct a First Article Manufacture meeting and prepare a quote letter with price breaks and other pertinent information.

Once you are ready to trial our services, we offer to make the first prototypes free-of-charge up to £500.00 in total including delivery.