Client Background

Our client is one of the UK’s largest suppliers of roof terrace pedestals, porcelain tiles and wood decking products. In recent years rooftop decking fire-rating requirements have evolved to remove wood and plastic from many buildings. Changes in regulations to mitigate fire risk have resulted in a need for new Fireproof A1-Rated products throughout the roof access and roof terrace markets in the UK and EU.

Client Brief

Our client required an adjustable steel pedestal to integrate into several of their existing rooftop decking product ranges. Our challenge was to support the design and then mass manufacture in volume a design that takes account of the typical sloping gradient on rooftops. Most A-1 fire rated products on the market at the time had fixed angles which meant they could not be used on raised commercial outdoor spaces.

WHY CHOOSE CEL FOR VOLUME MANUFACTURING?

Our client needed an on-shore supply chain partner that could support their initial CAD-design and prototyping requirements, and then mass produce at volume. We were able to deliver and then some.

FROM DESIGN TO MASS MANUFACTURING

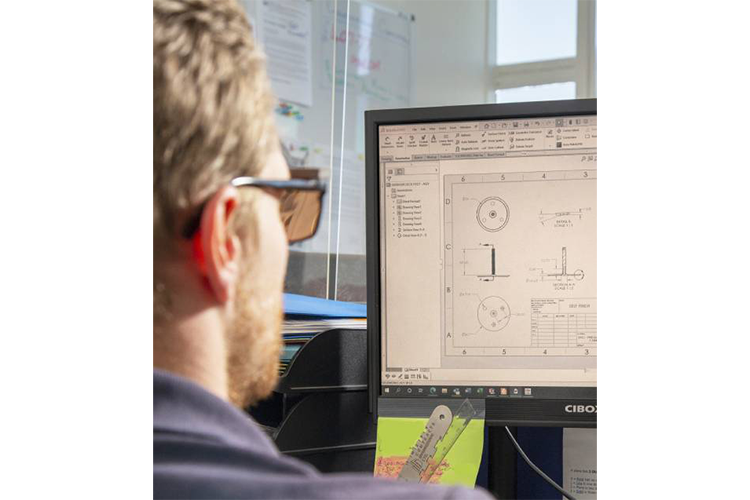

CEL’s Engineering team provided the initial 3-D CAD support and initiated discussions around manufacturing options and prices.

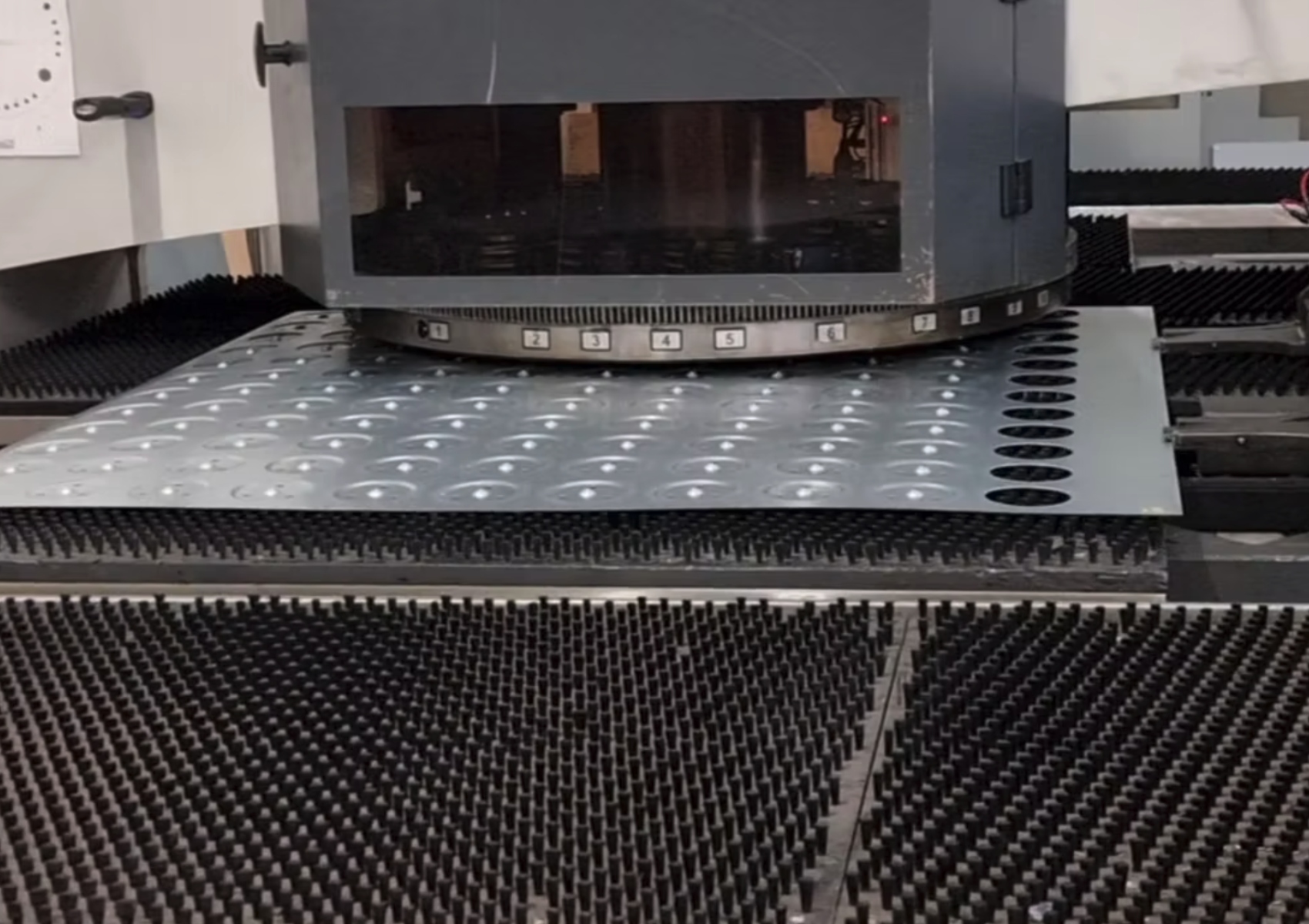

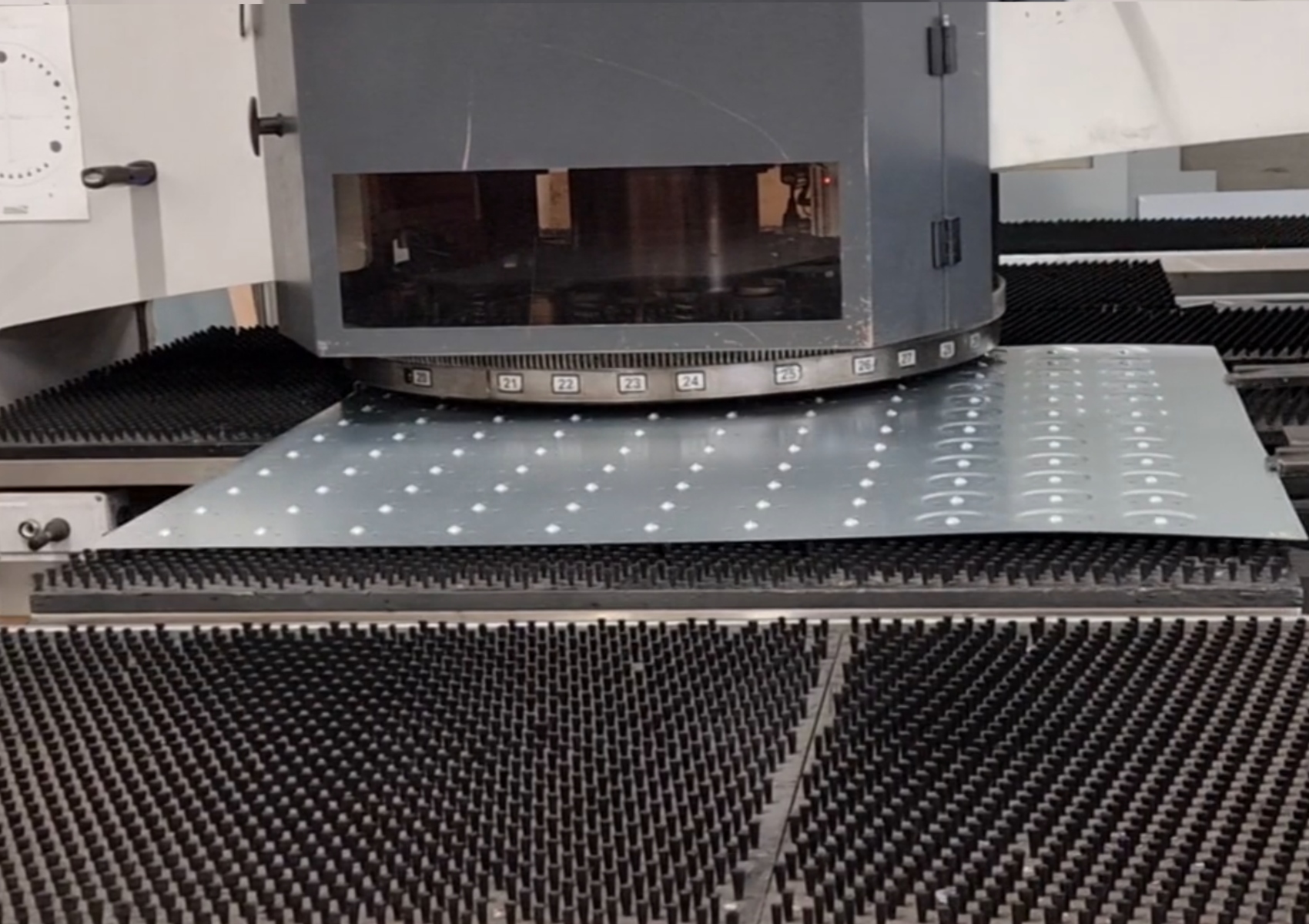

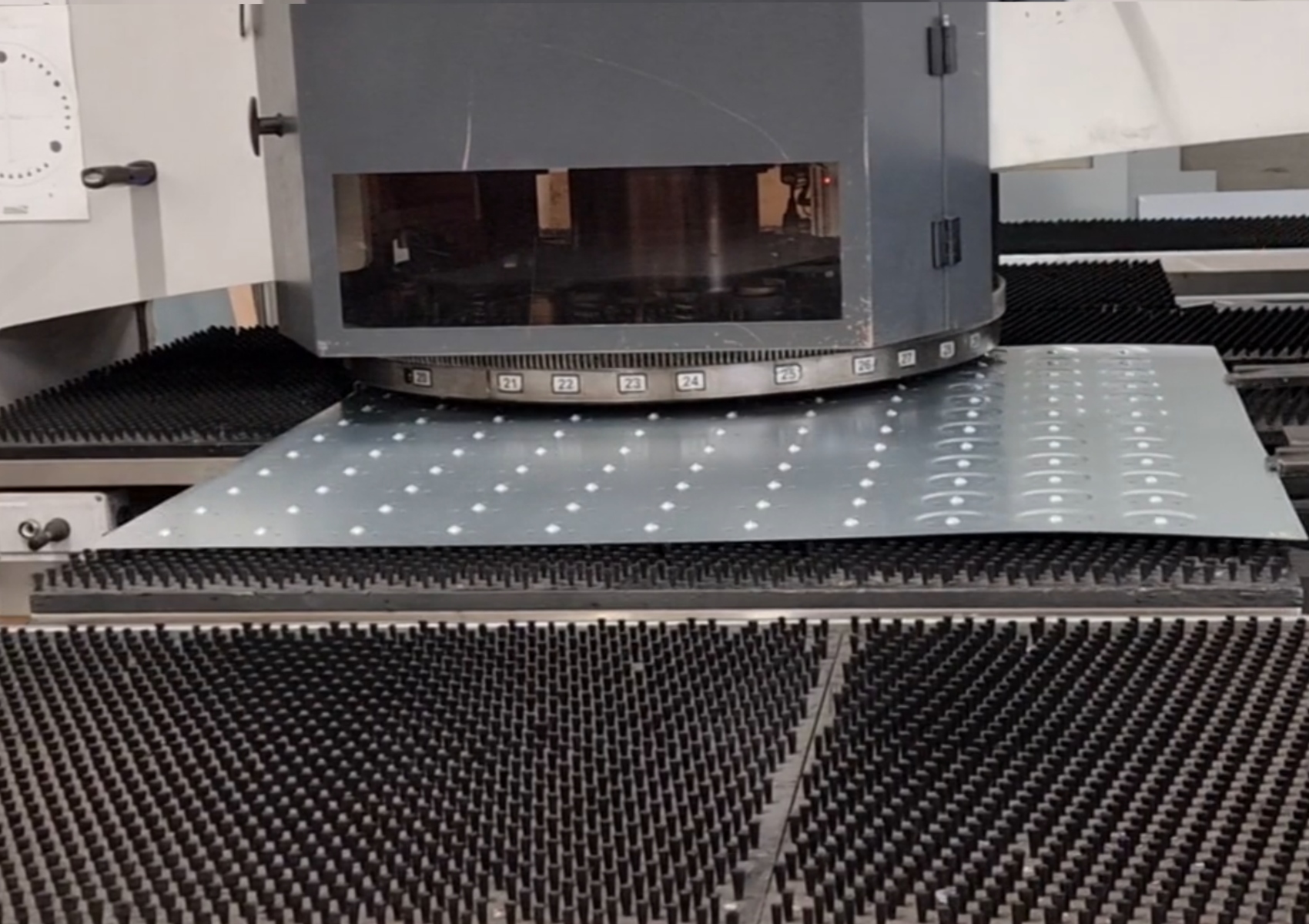

Our production team then began work analysing the required tooling investments before scheduling in the larger production run volumes through several of our work centres.

MASS MANUFACTURED

Working closely with our client on detailed weight loading and maximum correction adjustments, we developed several prototype designs and sent them to our client. We helped design a product that allows up to a 3.0o auto adjustment in any direction, allowing the pedestal to slope at standard gradients.

We have now produced more than 10,000 units and expect volumes to continue to increase to above +25,000 per year from 2022 and beyond.

MATERIALS USED

Pre-galvanized steel sheet, zinc plated and machined threaded rod and clinch-studs.

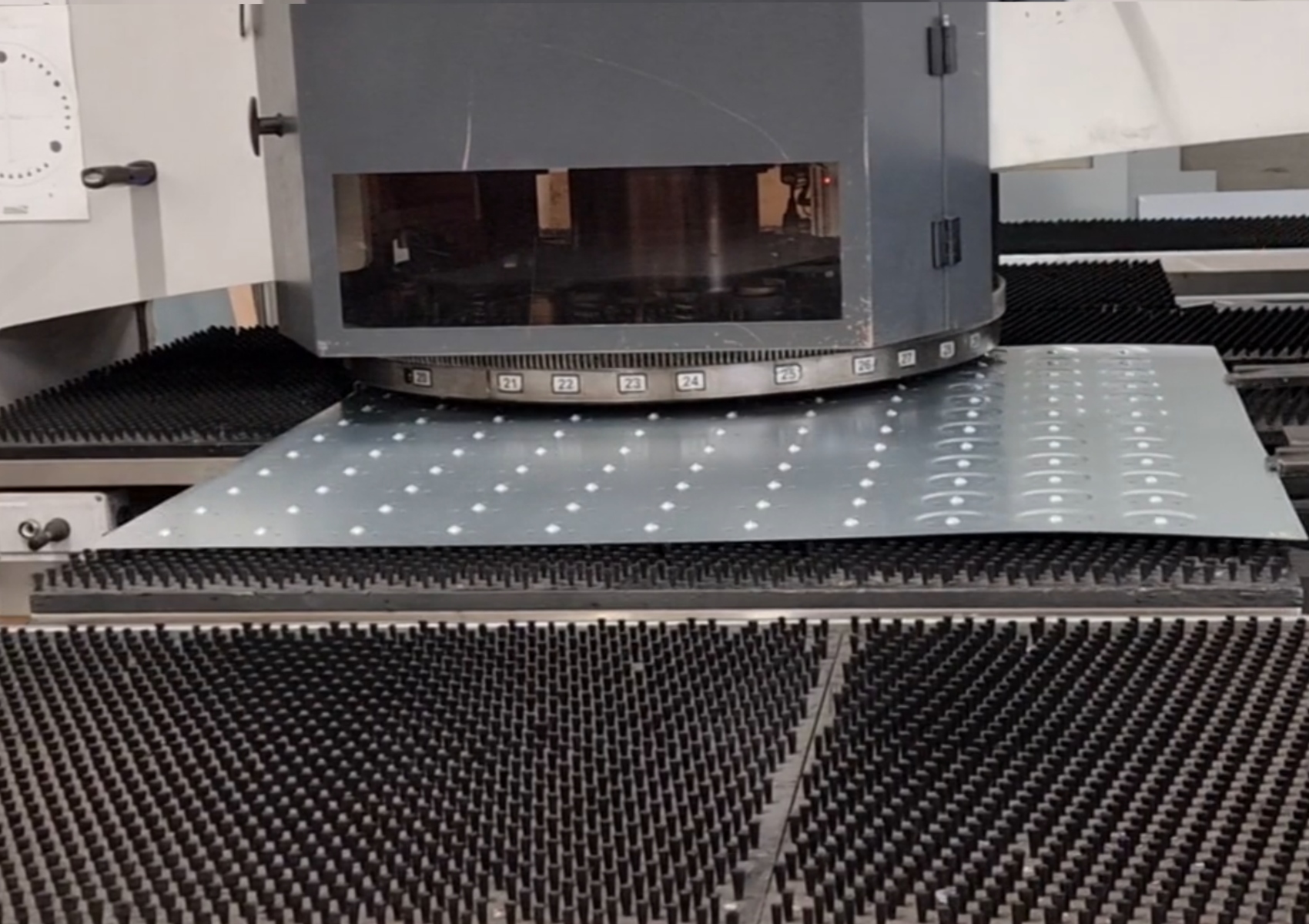

PROCESSES USED

Machining, form punching, CNC stud-insertion, plating, mechanical assembly and packaging.

We have worked with Contracts Engineering on a range of products and requirements over the past several years. This particular product has worked exceptionally well for us as we had to move quickly to comply with changing regulations and still offer products to meet our clients’ requirements. CEL did a great job from prototyping through to volume manufacture and we expect to sell in excess of 100,000 units per year going forward.