Client Background

Our client manufactures an extensive range of tables and seating as well as products for hotel kitchens. They supply to both the private and public sectors to help make the most efficient use of internal and external spaces.

Client Brief

Having standardised on a part that could be used extensively throughout their product range, our client needed to find a partner capable of offering consistent, high quality volume production with regular deliveries and fixed pricing over set periods of time.

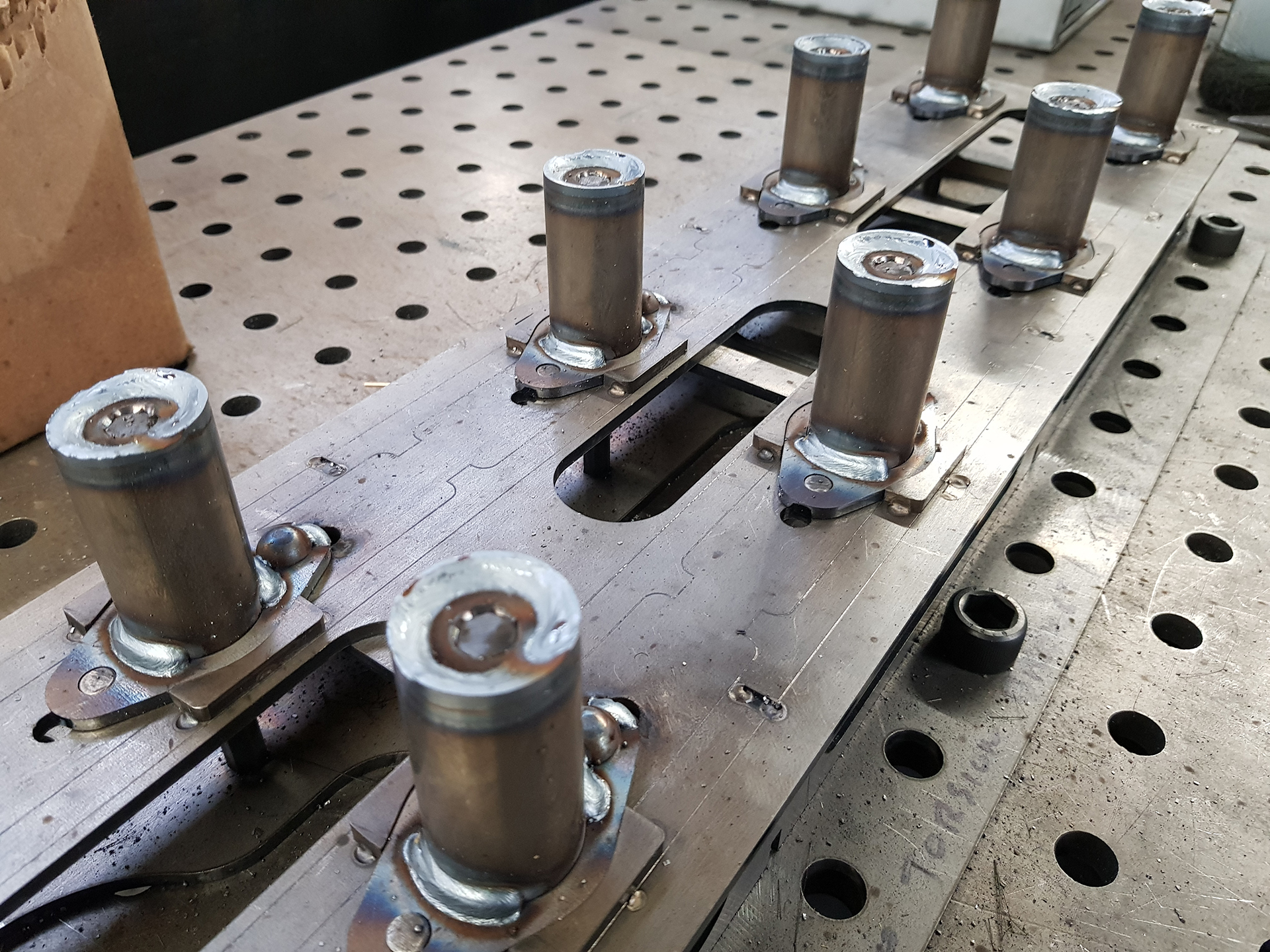

MECHANICAL ASSEMBLY

Our automated mechanical assembly production techniques provided the client with a high-quality product at volume. After carefully reviewing the customer’s needs, CEL determined this was the best way of achieving the high degree of accuracy and consistency required when producing 2,000 parts per month. Laser cut and free issue parts combined onto purpose designed fixtures so that each assembly could then be robotically welded and mechanically assembled.

INITIAL CEL SUPPORT

CEL communicated quickly and efficiently, first by phone and email and then set up a face-to-face meeting to discuss and understand our client’s urgent needs.

This information informed a First Article Manufacturing Meeting (FAM) bringing together our Engineering and Production teams to discuss and review parts and agree the best way to manufacture.

We provided free samples to our client for their quality assurance before ramping up to high-volume batch manufacturing.

CEL SOLUTION

We support our client with supply chain integration and six months fixed pricing arrangements and monthly deliveries, with the option to deliver weekly if required.

We were also able to provide quality assurance on the welds, using our SQL-based ERP system, ISO 9001:2015 accreditation and internal procedures that underpin our highest quality focus.

Services that we able to offer ranges from laser cutting, robotic welding and supply chain integration to fixed pricing agreements and packaging. Materials used included carbon steel end plate and body, a free issue carbon steel retainer and a flat head rivet.

Thanks to being able to offer consistent high quality and monthly deliveries, CEL have become this client’s go-to supplier for high production volume parts.

CEL continue to meet our challenging delivery requirements for this and many other parts. We find their proactive approach to be of immense benefit especially when trialling new products. We look forward to their continued support over the coming months and years.